Yinqiu boasts industry equipment, advanced processes, and a comprehensive intelligent production system. Our strong manufacturing capabilities provide solid support for integrated production, international marketing, service, and development.

In terms of production automation, the company has prioritized industrial automation since its inception. Early on, Yinqiu began building its own automated production lines and later acquired industrial robotic arms to further enhance automation. In 2013, the company purchased multiple articulated robots and established an articulated robot laser welding workshop.

-

Innovative Design and R&DWe focus on innovative design and R&D, continuously investing in technological innovation. Our dedicated R&D team is committed to developing new kitchenware hardware components and kitchen appliance accessories. Through constant experimentation, testing, and improvement, we introduce forward-thinking and market-competitive products.

-

Technical Collaboration and PartnershipsWe actively collaborate with technical partners and suppliers to leverage external innovation resources. By partnering with industry experts and research institutions, we stay updated on the latest technological trends and integrate advanced technologies into our product design and manufacturing processes.

-

Application of Digital TechnologiesWe utilize digital technologies such as Computer-Aided Design (CAD) and simulation for product design and production. These technologies enable precise design, rapid validation of solutions, and improved efficiency and quality.

-

Continuous Improvement and Feedback MechanismsWe have established a robust feedback mechanism and continuous improvement system. Regular market and customer feedback surveys help us incorporate user experience and needs into product innovation, optimizing performance and functionality to enhance competitiveness.

-

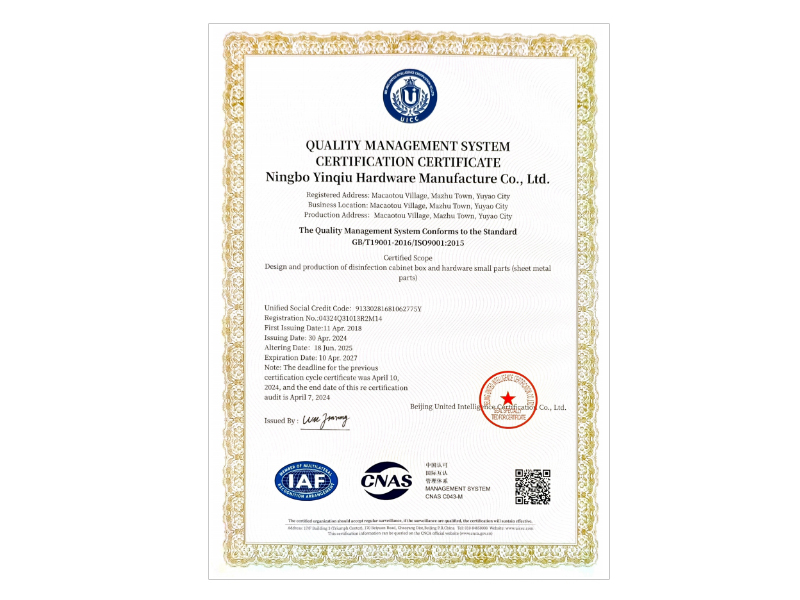

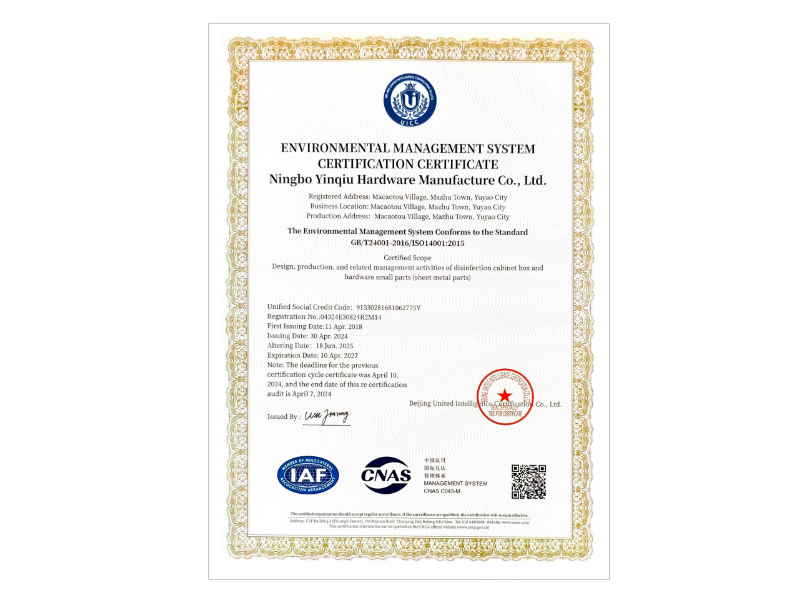

Strict Quality Management System

We have established a comprehensive quality management system, with strict quality control measures at every stage—from raw material procurement to production and final product delivery. In 2006, we obtained ISO9001 Quality Management System certification and ISO14001 Environmental Management System certification. Later, we implemented 6S management, lean production management, Six Sigma management, and zero-defect management, significantly improving our management standards.

-

Supply Chain Quality Control

In addition to stringent quality control in our own production processes, we have established close collaborations with suppliers to ensure the reliability and stability of raw materials. This guarantees the quality of the final products.

-

Advanced Production Processes

We employ advanced production technologies and equipment to ensure efficient and precise production processes. By continuously optimizing production techniques and introducing advanced production lines and equipment, we enhance both production efficiency and product quality.

-

Rigorous Product Testing and Inspection

Throughout the production process, we conduct multi-level product inspections and rigorous testing. From raw material inspection to semi-finished and final product testing, we ensure that every stage of production meets quality standards. Multiple tests are performed to ensure stable and reliable product performance.

English

English